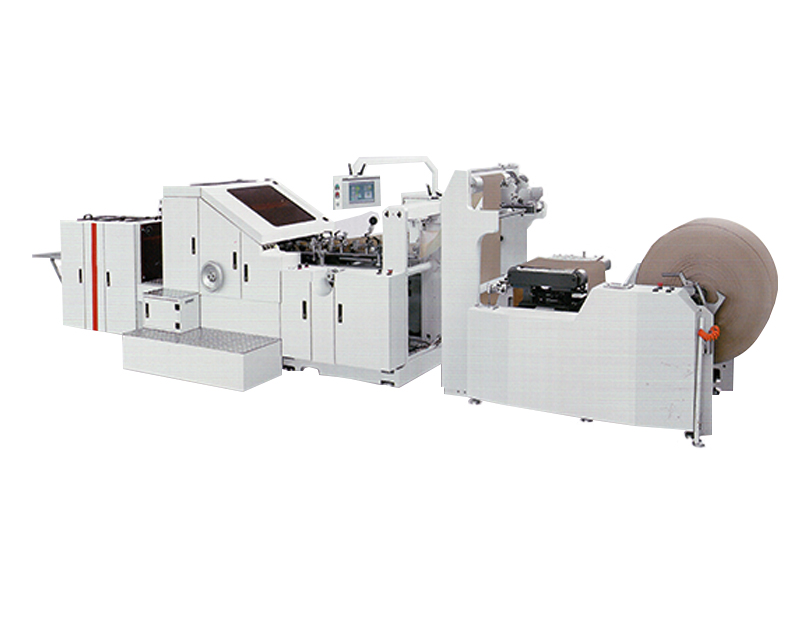

Properties and uses:

Rolling feed square bottom paper bag making machine, it uses paper roll in blank or printed as raw material. consists of automatic centre forward glue, printing tracking, fixed length and cutting, bottom indentation, folding bottom, bottom glue. Bag bottom forming, finished bag collecting one time,The machine is more convenient, more efficient, more stable, can produce a variety of different paper bags, leisure food bags, bread bags, dried fruit bags and so on environmentally friendly paper bag machine equipment.

Main features

1.Use France Schneider Touch Screen Human-Computer Interface, operate and control easily.

2.Adopt Germany Original REXROTH PCControl, integrated with optical fiber, ensure high speed running steadily.

3. Germany Original REXROTH Servo Motor and Germany Original SICKPhotoelectric Eye Correction, tracking printing bag accurately.

4.Raw material load adopt electrical motor up and down structure, unwinding adopt auto tension control.

5.Raw material unwinding EPC adopt Italy SELECTRA, Reduce adjustment time.

Technical parameter

| Model | HRT-B190 |

| Cutting length C | 190-370mm |

| Paper bag width W | 80-200mm |

| Paper bag bottom width H | 50-105mm |

| Paper thickness | 50-130g/m2 |

| Machine Speed | 30-200pcs/min |

| Paper bag speed | 30-180 pcs/min |

| Paper roll width | 300-640mm |

| Roll paper diameter | 20-1200mm |

| Machine power | 3phase 4line 380V 14kw |

| Machine weight | 5600kg |

| Machine size | 8500x2100x1600mm |

Paper Bag Technology Flow Chart

| *1. The computer interface of the machine can be set point mark function, which is advantage us for packing quantity and convenient for collecting and arranging. |  |

| *2.Bottom forming part of bag bottom. |  |

| *3.Bottom glue structure, groove type glue up device. |  |

| *4.The machine cut off way adopts the servo motor to control the paper bag size, adopting high-speed uniform rotation cutter, cutting through the tooth knife or flat knife two cutting methods, the paper bag cutting level, making the paper bag cutting Flat, beautiful. |  |

| *5.The whole type tube is used to adjust the structure, and the two-way adjustment or one-way adjustment is simple and convenient, and the fast and precise high stability of the adjusting is stable. |  |

| *6.Using the German (sick) color photoelectric tracking, precise tracking of paper printing photo, automatic alignment, if change the paper roll, power does not need to adjust the cutting position. Automatic stop if color error ,reduce Scrap rate. |  |

| *7.The automatic spray glue, the glue spray will not be interrupt when hign speed or low speed, convenient adjustment capacity, glue spray stable. |  |

| *8.The use of ultrasonic simulation alignment the side, the reaction speed of the operation of a quick correction ,save time and save the waste of raw materials. |  |

| *9.Adopt hydraulic cylinder auto loader, paper manual switch easily finish the paper roll without manual handling. |  |

Price Terms

| Description | FOB Price |

| RZFD-330AUTOMATIC HIGH SPEED SQUARE BOTTOM PAPER BAG MACHINE | 106,000 USD |

| Payment | After signing of the contract ,the total amount of 30% advance payment, factory acceptance payment before delivery after the machine testing is ok. |

| Delivery time | About 75 working days after receiving the deposit. The factory will decide whether to change the delivery date when the order is confirmed. |

| Electrical Equipment | This machine adopts three-phase 380. If you have any special requirements, please explain in advance with my company.. |

| Guarantee | We offer a 12 month warranty. During the warranty period, we provide free replacement of damaged parts due to quality problems. All failures caused by improper use of the buyer (including unauthorized modification of PC and touch screen built-in software) are not within the scope of the warranty. (except for the vulnerable parts of wearing parts). |

Packaging & Delivery

Packaging Details:

We usually packed this machine covered by plastic film.

Delivery Detail:

Within 30 days after we got the deposit.

Copyright © Shandong Rino International Trade Co., LTD. All Rights Reserved. | Sitemap | Powered by